[Image above] Credit: Derek Gavey; Flickr CC BY 2.0

Radar makes a lot of stuff possible—stuff we take for granted in our everyday lives, including traffic control, marine location, weather forecasting, air defense, and flight control systems.

Because radar uses radio waves to detect the position, direction, and speed of objects, radar sensors also might play an increasingly important role if the autonomous vehicle trend pans out in the near future.

And if the cars are driving themselves, you better believe their radar sensors need to be durable, precise, and reliable.

One of the ways to make sensors more reliable is to develop them with materials that perform better than alternatives—and glass–ceramics are a prime candidate because the sensors need to be able to operate at high frequencies, yet do so precisely and efficiently.

In those sensors, glass–ceramic materials called low-temperature cofired ceramics (LTCC) can make up layers in the circuit board, to which an antenna is mounted to the top. The board’s materials directly influence the properties of the antenna’s operation, so the ability to adjust properties of the glass–ceramics is important for controlling sensors’ performance.

Now researchers at Technische Universität Wien have developed a simple nanostructuring technique that can precisely control the electromagnetic behavior of glass–ceramic circuit boards.

Although some attempts to adjust circuit boards’ properties have incorporated organic materials along with glass–ceramics, transitioning between materials is not ideal because of differing rates of heat expansion of the materials.

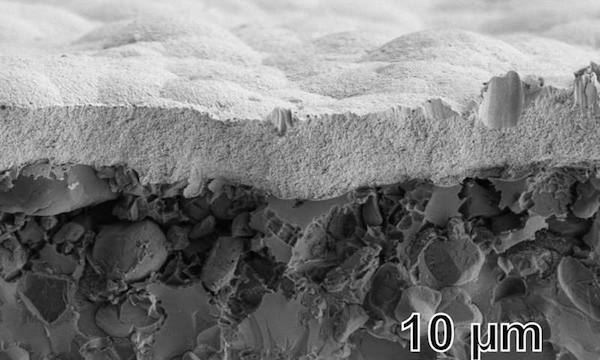

To adjust the properties of sensors without incorporating differing materials, the TU Wien team instead toyed with the glass–ceramics’ properties themselves. The scientists developed an acid-etching technique that removes feldspar from the fired material, leaving a nanoporous structure.

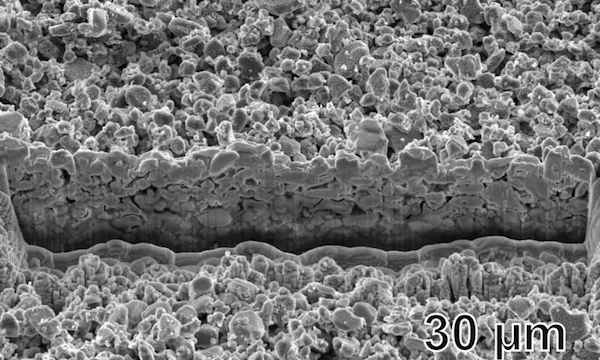

Pulse plating created a consistent metal layer on the glass–ceramics’ porous surface. Credit: TU Wien

“Prior to the acid treatment, the permittivity measures between seven and eight but the nanopores reduce it by up to 30%. Not only that, but this can be achieved with a minimum of technological effort and using conventional tape systems that were not even produced with this etching process in mind. That is impressive,” researcher Achim Bittner says in a TU Wien press release.

Not only can the technique improve performance of sensors, but it also affords control over the manufacturing process. “The new etching technique can be used with pinpoint accuracy to imbue different parts of the glass–ceramics with different properties,” the release states.

This flexibility could enable connected multi-antenna arrays that are more precise or afford new capabilities to the sensors.

The team has already partnered up with electroplating company Happy Plating (Austria) and other European partners to manufacture antenna circuit boards from the new materials “with very promising results.”

The release adds that “there are also plans to use the technique as a diagnostic method in the future to find out more about the behavior of the glass–ceramic material with a view to improving it further at a fundamental level.”