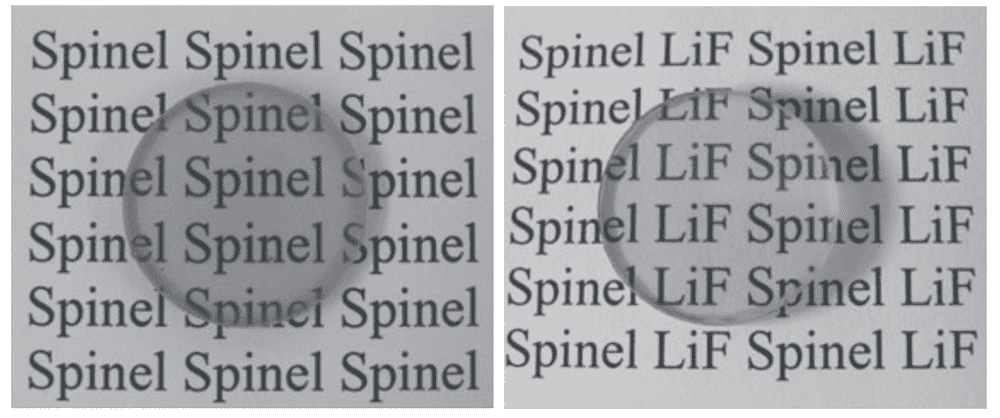

Lithium metazirconate (LZO) has demonstrated promise as an electrode coating in solid-state batteries, and some researchers are exploring the use of LZO as a solid-state electrolyte itself. However, to date, all electrochemical testing on LZO for this application has been performed on pressed discs rather than thin films. Researchers in Argentina and Spain developed an aqueous forming route to obtain LZO films by tape casting.

Read MoreTo celebrate the milestone of the 20th volume of the International Journal of Applied Ceramic Technology, the editorial team assembled a selection of journal papers representing the excellent work from the advanced ceramics community. The focus this month is porous ceramics.

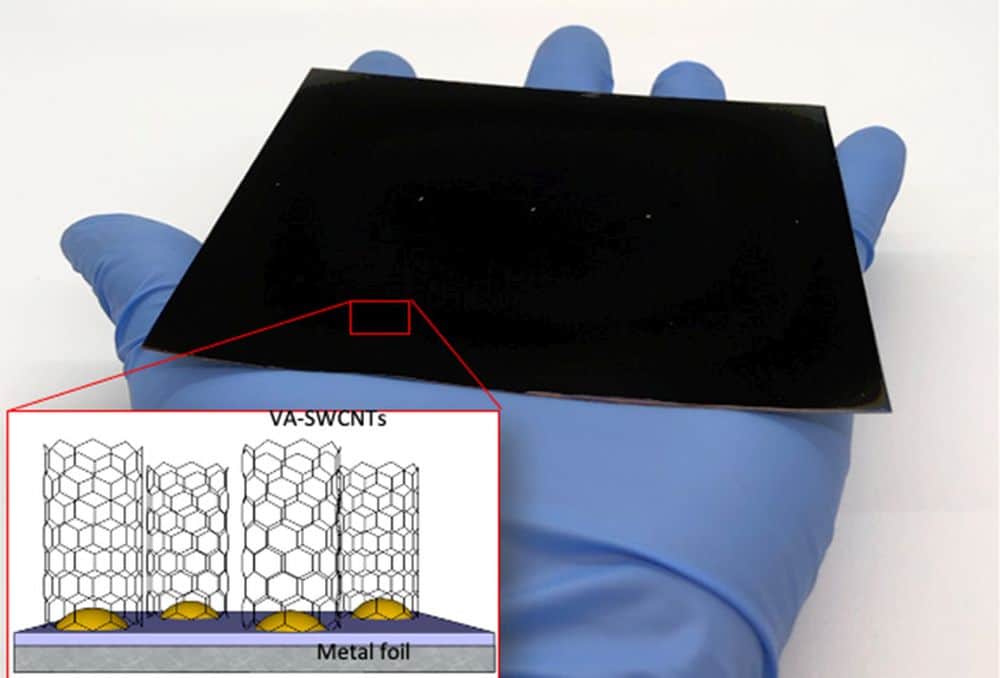

Read MoreGrowing carbon nanotubes on metal foils rather than traditional silicon or quartz substrates would allow the process to be easily integrated into large-scale manufacturing processes. But metal foils present other challenges, such as reactivity at high temperatures. Lawrence Livermore National Laboratory researchers published a review paper summarizing efforts to overcome these challenges.

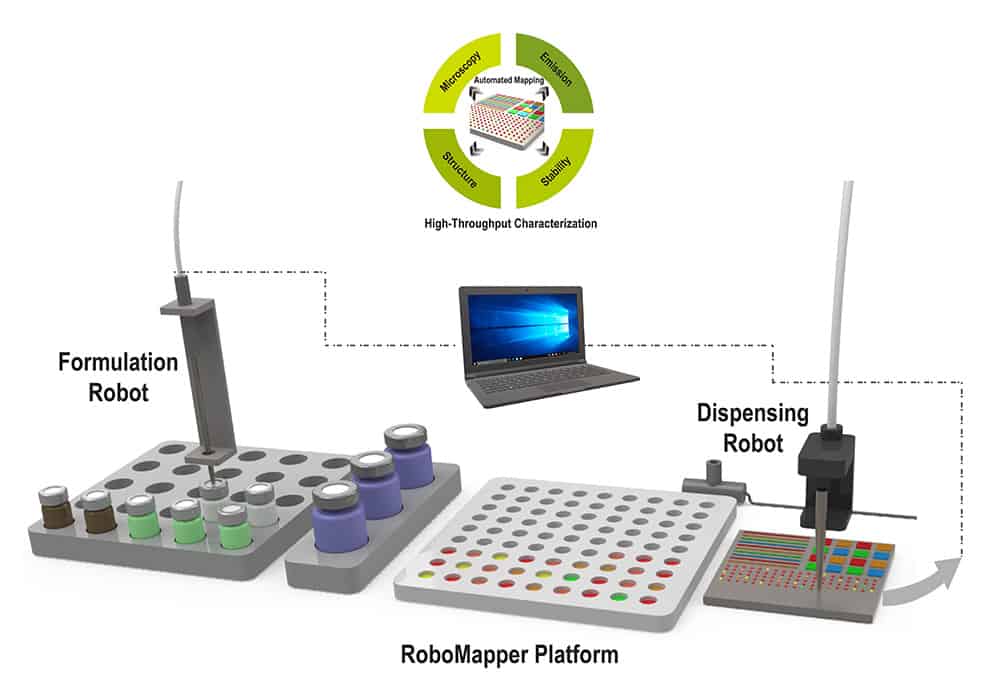

Read MoreAutomating experiments can help speed up the materials development process. Researchers led by North Carolina State University developed a new high-throughput automated testing system that deposits multiple samples on the same substrate, thus saving time and energy.

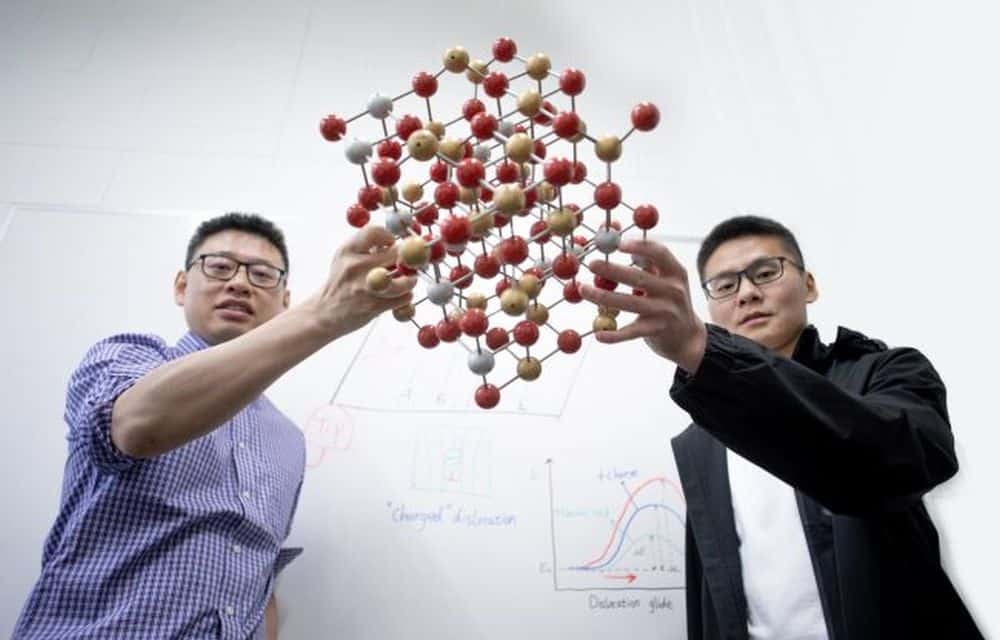

Read MoreWhile some studies have demonstrated that electric fields and light exposure can affect the motion of dislocations in ceramics, the principal driving force of motion in these cases was mechanical stress. Now, an international group of researchers showed dislocation motion in a single-crystalline zinc sulfide can be controlled using only an external electric field.

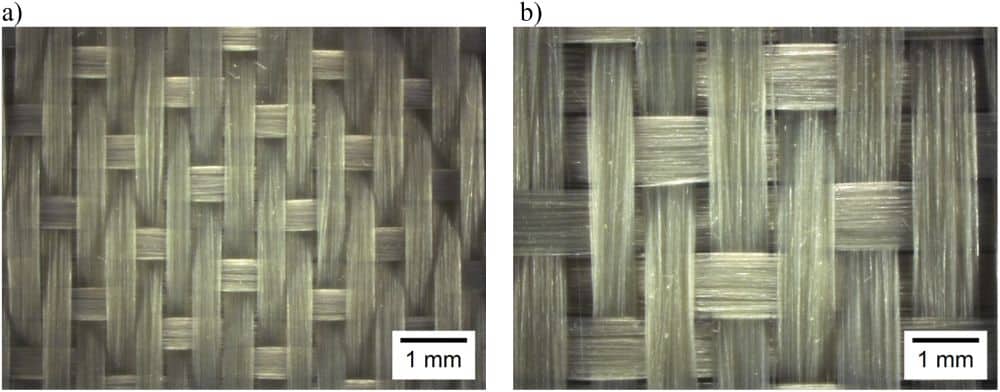

Read MoreBalancing cost and quality is an important consideration for manufacturers and researchers looking to commercialize their innovations. Researchers in Germany explored the tradeoffs that come with creating all-oxide ceramic matrix composites from fiber bundles with higher filament counts.

Read MoreInstead of open-pit mines, tailings may become the primary source of feldspar and quartz in the future if the minerals can be selectively extracted from the waste. Researchers in China showed that hydroxypropyl starch can improve the flotation separation of feldspar and quartz.

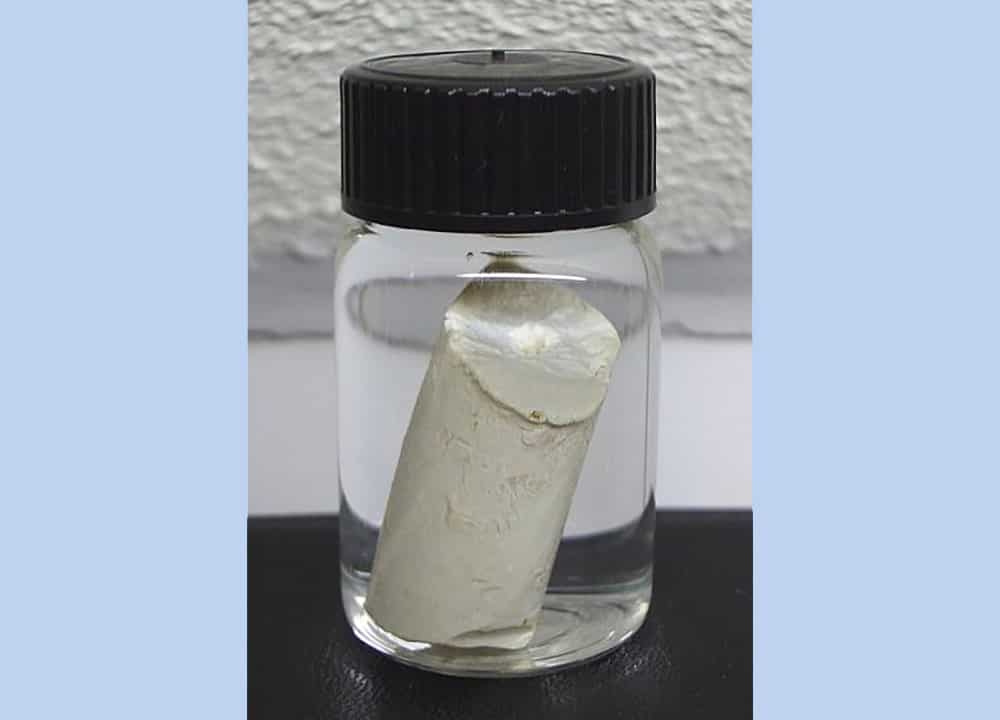

Read MoreWhite phosphorus is a synthetic form of phosphorus used to produce many commodity chemicals. But the conventional process for producing white phosphorus has a high carbon footprint. Researchers at Massachusetts Institute of Technology developed a molten salt synthesis process for white phosphorus production that is more cost effective and environmentally friendly.

Read MoreTo celebrate the milestone of the 20th volume of the International Journal of Applied Ceramic Technology, the editorial team assembled a selection of journal papers representing the excellent work from the advanced ceramics community. The focus this month is advanced sintering.

Read MoreHumic substances are beneficial to agriculture, but they can aggravate pollution in water by interacting with disinfectants to produce toxic byproducts. Hydrogarnet has shown excellent potential as an adsorbent for humic substances, and researchers in Japan investigated the effects of heat treatments to control hydrogarnet composition and adsorption properties.

Read More