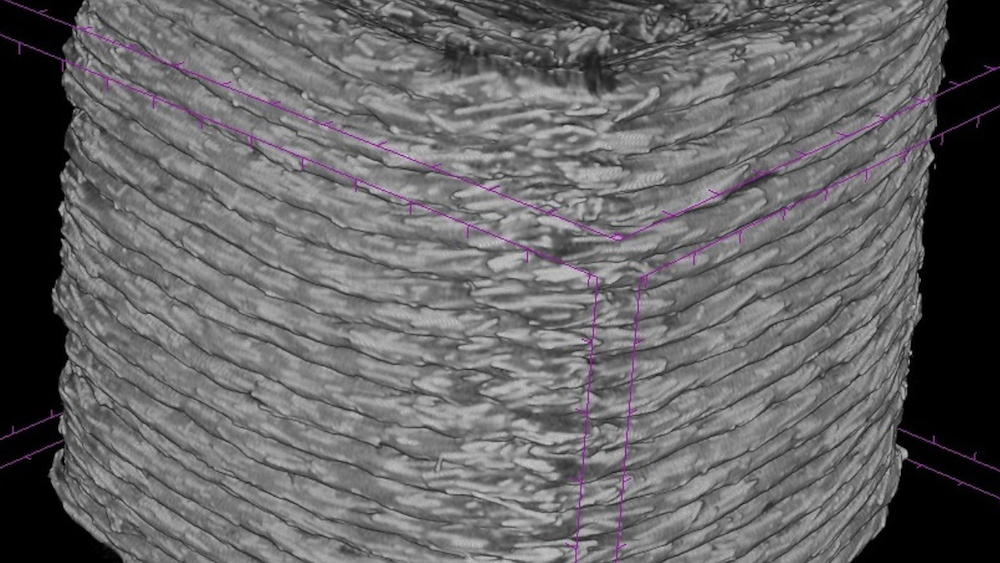

[Image above] A 3D view of a reconstructed CT scan model of a 3D-printed composite part showing overall dimensions and geometry. Credit: Nikhil Gupta, New York University Tandon School of Engineering

Ever since Colorado-based additive manufacturing (AM) consultancy firm Wohlers Associates published the first edition of the annual Wohlers Report in 1996, the state of the global 3D printing and AM market has changed enormously.

The annual report provides insight into the benefits and challenges of the global AM industry, and this year’s report paints a rosy picture of continued growth, particularly regarding maturing and emerging applications of AM for series production.

Though much of the report’s discussion centers on polymer and metal AM, these materials are not the only ones driving AM advances. We’ve covered quite a few advances in ceramic, glass-ceramic, and glass AM on CTT as well, with more studies appearing regularly in the weekly “Other materials stories” column.

One reason AM is gaining so much steam is because of the extreme standardization such techniques offer. Once researchers identify an ideal structure that optimizes desired material properties, they can create a computer-aided design (CAD) file that tells a 3D printer exactly how to print that structure—resulting in the ability to mass produce optimized materials in a reliable manner.

It is no surprise these CAD files are a valuable trade secret for manufacturers—if someone had the files, they could create the optimized material themself (assuming they had a 3D printer and knew the composition, of course). Securely protecting these files, then, is an important goal in industry.

Unfortunately for manufacturers, a new study shows that even when CAD files are securely protected, people may still be able to steal the optimized design.

The new study comes from researchers at the New York University Tandon School of Engineering. And in their paper, they argue machine learning could present a security risk for manufacturers.

Machine learning is an emerging data science technique that is poised to play a big role in speeding up materials discovery and commercialization. “While [machine learning] methods are enabling composite material design, they may also be used for reverse engineering of products, which is the focus of the present work,” the researchers write.

In their study, they used a supervised machine learning algorithm called a recurrent neural network (RNN) to analyze micro-CT scan images of a 3D-printed part’s microstructure. In particular, they looked to determine the part’s fiber orientation and print direction because that would reveal the CAD file toolpaths, i.e., the programmed paths through space that a tool follows on its way to producing the desired geometry of a part.

After training the RNN algorithm on thousands of images of glass-fiber reinforced polymer filaments 3D printed via fused filament fabrication, the researchers checked the algorithm’s accuracy and found it predicted printing orientation of the fiber with little error (less than 0.5°), and the dimensions of reversed engineered models differed from original models by only 0.33%.

“Although the part geometry is simple in the current example, the success of the [machine learning] method in identifying tracking any given orientation of the fibers demonstrates the possibility of reconstructing the G-code and reverse engineering any composite part,” they write in the paper.

In an NYU press release, Nikhil Gupta, professor in the Department of Mechanical and Aerospace Engineering at NYU, notes their findings are an important wake-up call for manufacturers as AM becomes a standard technique used in industry.

“The security concerns should also be a consideration during the design process and unclonable toolpaths should be developed in future research,” he says.

The paper, published in Composites Science and Technology, is “Reverse engineering of additive manufactured composite part by toolpath reconstruction using imaging and machine learning” (DOI: 10.1016/j.compscitech.2020.108318).