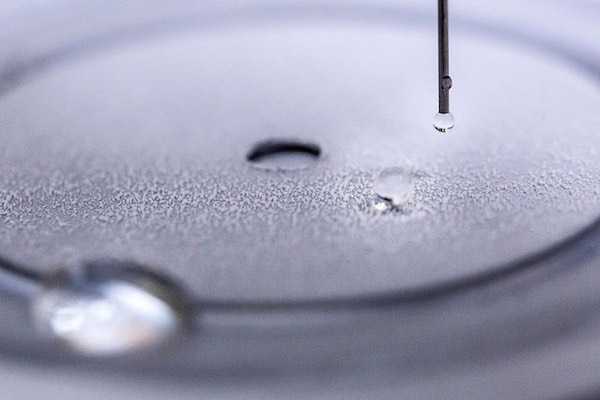

[Image above] A water droplet bounces off a superhydrophobic coating developed at the University of Michigan. Credit: Joseph Xu; Multimedia Content Producer, University of Michigan – College of Engineering

“Thousands of superhydrophobic surfaces have been looked at over the past 20 or 30 years, but nobody has been able to figure out how to systematically design one that’s durable,” according to University of Michigan associate professor of materials science and engineering Anish Tuteja.

We’ve covered several of those surface developments here at Ceramic Tech Today, including innovation inspired by penguins and even self-cleaning paint.

Just last year, Tuteja and a team of Michigan researchers developed a spray-on rubbery surface coating for keeping ice at bay. And others have developed super surfaces using nanoparticles and carefully patterned nanostructures.

But, as Tuteja commented, the problem is durability.

For an engineer, however, a problem is also an opportunity.

According to a recent University of Michigan press release, Tuteja’s team has now developed the ultimate superhydrophobic spray-on coating that is so durable that it can be applied to virtually any surface, including vehicles, boats, clothing, and more.

The slightly rubbery coating—a mixture of fluorinated polyurethane elastomer and F-POSS water-repellent molecules—is extremely durable because it can heal itself after being chemically or mechanically damaged.

Watch the researchers put the surface coating to the test—with a full battery of attacks—and see if it can stand up to the abuse in the video below.

Credit: Michigan Engineering; YouTube

What’s the secret to this surface’s success?

“Most materials science researchers have focused on identifying one specific chemical system that’s as durable and water-repellent as possible,” Michigan doctoral student Kevin Golovin says in the release. “We approached the problem differently, by measuring and mapping out the basic chemical properties that make a water-repellent coating durable. And some of the results surprised us.”

For instance, the researchers found that partial miscibility of the ingredients that come together to make up the coating are more important than the individual durability of those ingredients themselves.

And instead of focusing on the geometry of nanofeatures on the surface of the coating, the researchers instead found that designing a surface that’s slightly pliable makes it even more durable, because it can recover from damage more easily that more rigid architectures.

According to the release, Tuteja founded a company to commercialize the technology, called HygraTek, and expects these super coatings could be available for consumer use by the end of 2017 for applications such as water-repellent fabrics and spray-coatings.

The paper, published in ACS Applied Materials & Interfaces, is “Designing self-healing superhydrophobic surfaces with exceptional mechanical durability” (DOI: 10.1021/acsami.6b15491).

Graduate students Mathew Boban and Kevin Gloving test a superhydrophobic surface by burning it as part of its resistance testing against water. Credit: Joseph Xu; Multimedia Content Producer, University of Michigan – College of Engineering