What are ceramics and glass?

While most people are familiar with everyday ceramic and glass materials, these materials are used for much more than just pottery, dishes, and windows. As you will learn, Ceramics are Cool! Check out the resources below to learn more about these amazing materials.

Ceramic and glass materials enable advanced technologies—sometimes as components in devices, sometimes as materials necessary for manufacturing other materials. Components include catalytic converter substrates for your car, fiber optic glasses that bring the internet to you, light bulbs, and dental crowns. Behind the scenes, refractory ceramics line steelmaking furnaces and cement kilns, draw heat out of your cell phone, and project jet engines during flight.

Broadly speaking, ceramic materials are nonmetallic, inorganic materials, that is, not metals, not plastics, not organic chemicals. Compounds such as oxides, nitrides, carbides, and borides are generally considered ceramic materials. Glasses are amorphous materials with a wide composition ranges. However, most commercial glasses are silicate or borosilicate based compositions.

Everywhere you look, ceramics and glasses are hard at work—even though they may be unseen. Explore the links below to learn how ceramic and glass materials are used everyday!

Learn more about ceramics and glass in our world

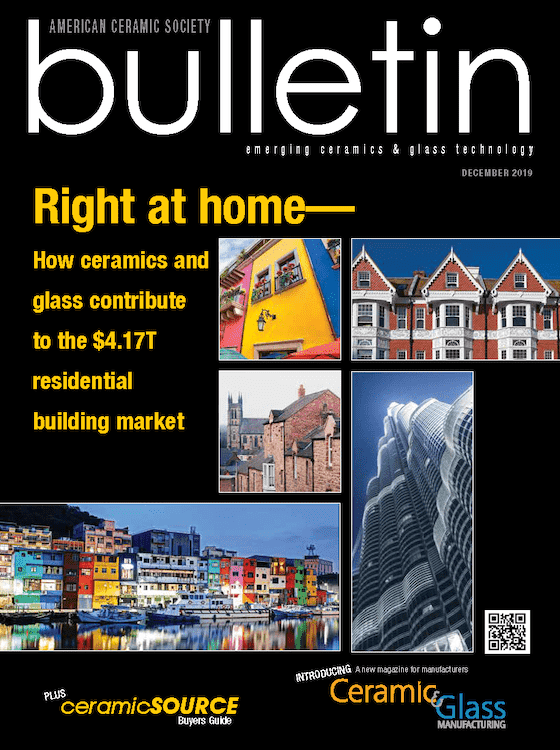

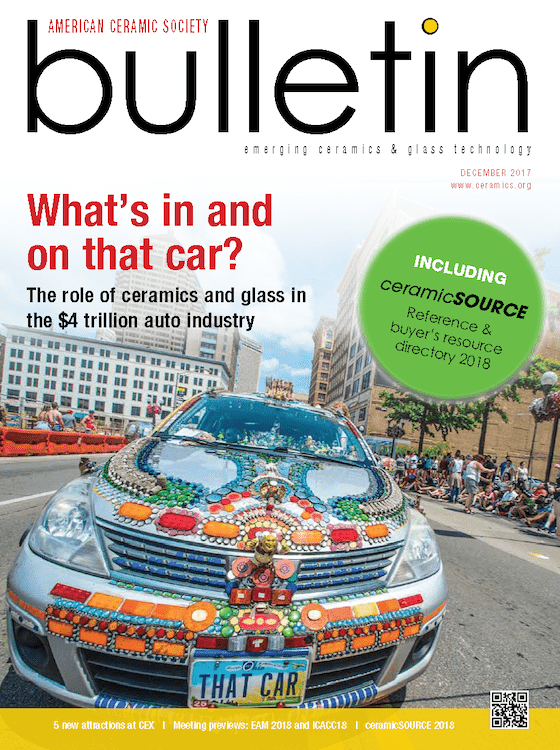

Want to learn more about the role ceramic and glass materials play in your everyday life? Each winter, the December issue of the ACerS Bulletin provides an in-depth look at the ceramic and glass materials used in different areas of your life, including in our homes, bodies, electronics, and more. View all the December feature articles below, and learn more about ceramic and glass global markets through the October/November Bulletin international issues.

Become an ACerS member and access all 100+ years of ACerS Bulletins through the Bulletin Archive Online!

This is ceramics!

Want to learn even more about how ceramics and glass impact our world? Follow ACerS Fellow Ricardo Castro on LinkedIn, where he shares surprising insights about ceramic and glass applications under the hashtag #thisisceramics.

Resources

Want to learn even more about ceramics and glass? The resources below offer a starting point to learn more about these materials!

General materials science resources

Ceramic and glass resources

ACerS members are materials scientists who specialize in ceramic and glass materials.

Materials matter because everything is made of stuff!

Eleven Divisions focus on specific materials and applications.

Read the latest industry news and trends.

Branches of ceramics

Most people are familiar with traditional ceramics used in everyday objects such as dishes, pottery, sanitaryware, brick, art. Similarly, we are accustomed to glass in windows, drinking glasses, microscope optics, and fish tanks.

However, advanced ceramics and glass contribute in obvious and hidden ways. Examples include catalytic converter substrates in vehicles, cover glasses for smartphones and tablets, refractory linings of steelmaking furnaces, fiber optics for the internet, bone cements, ceramic armor, cutting tools, and much more.

From better brick to today’s advanced ceramics and glass

Brick manufacturers founded ACerS in 1898 to apply scientific methods to manufacturing of clay products. Today, ACerS members research, develop, manufacture, and design engineered ceramics and glasses for use in nearly every technology.