ACerS: The home for ceramic and glass professionals.

ACerS members gain invaluable benefits. Learn more.

Check out our highly regarded journals, magazines, books, and more!

ACerS meetings offer opportunities to network with ceramic and glass experts.

Be sure to check out and support our amazing corporate partners.

The latest in ceramic and glass news from around the world. Also—Society news.

Visit the ACerS Learning Center

There's always something new to learn in ACerS Learning Center. Learn a new skill or add to your existing knowledge in ACerS Learning Center.

ACerS Members

Log in for access to exclusive members-only content.

Check out all of ACerS learning options!

We have a great lineup of ceramic and glass conferences.

The American Ceramic Society announces has return to in-person meetings for Q4 of 2021 and beyond. ACerS and its Meetings team will continue to comply with guidance from the Centers for Disease Control, relevant state and local authorities, and each conference venue in an effort to provide a safe and healthy environment for our meeting attendees during the ongoing COVID-19 pandemic.

49th International Conference and Expo on Advanced Ceramics and Composites

Daytona beach, FL, USA

January 26 - 31, 2025

Here's the latest from ACerS.

Novel glass systems and sustainable processing, plus more inside May 2024 ACerS Bulletin

The May 2024 issue of the ACerS Bulletin—featuring an overview of chalcogenide glasses—is now available online. Plus—approaches to sustainable glass processing.

Ceramic Tech Today

See what ACerS members have achieved.

Diamond Corporate Partners

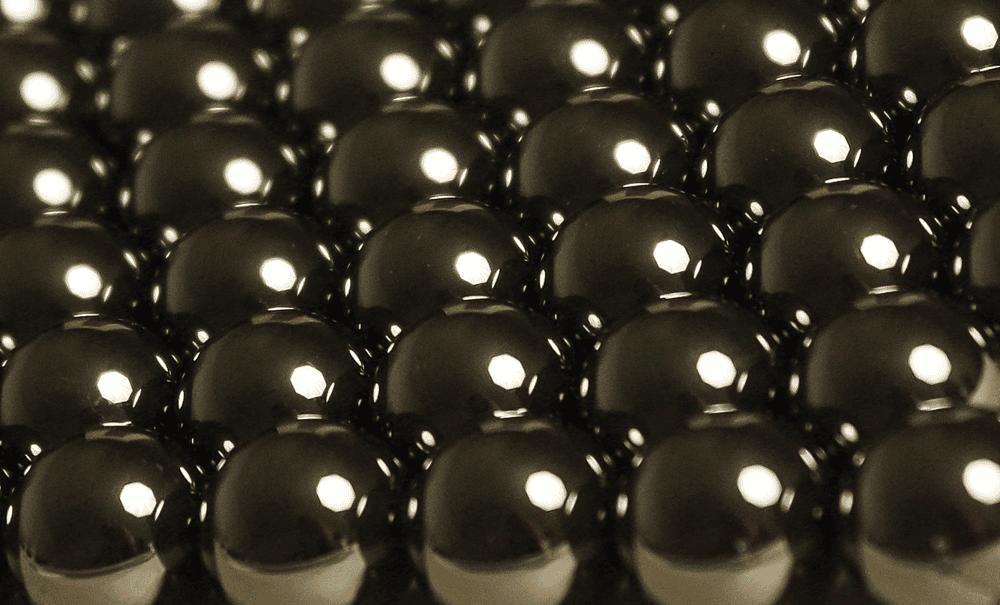

Learn more about our Diamond Corporate Partners.

Publications & resources

Review our comprehensive catalog of publications.

From groundbreaking fundamental research to models of atoms, energies, mechanisms, processes and systems, articles published in ACerS's four journals have a lasting impact on our field.

Read More

Over 27,000 critically evaluated diagrams for understanding temperature-dependent material interactions in ceramic and inorganic systems.

Read More

The industry’s undisputed authority on news and new developments in the ceramics and glass industries.

Read More

Resource Center

Tools for the ceramic and glass trades.

Ceramic and Glass Industry Foundation

The Foundation is a global partnership among organizations devoted to science, engineering, and technology of ceramics and glasses.

The American Ceramic Society (ACerS) stands for inclusivity. We are saddened and disturbed by recent events that have shone a light on the systemic racism, discrimination, and inequality that exists today. ACerS strives to be a leader by working toward solutions now and moving forward. ACerS seeks to foster an environment promoting the free expression and exchange of scientific ideas for its entire international community. We are committed to ensuring equality of treatment and opportunity and freedom from harassment for all members regardless of race, gender, nationality, religious beliefs, gender identity, color, age, marital status, sexual orientation, disabilities, ancestry, personal appearance, or any other basis not relevant to scientific merit. Any violation of our harassment or discrimination policies is addressed immediately by Society leadership, and not tolerated. Finally, ACerS has an active Diversity & Inclusion Subcommittee that works with Society leadership to seek ways to be inclusive of all people.

To read our anti-harassment policy, please click here. To read our Code of Conduct policy for ACerS events, please click here. To read our statement against hate, please click here. To learn more about what ACerS is doing to cultivate a diverse, inclusive, and equitable environment, visit our "Diversity & Inclusion" webpage.